Antirust TPR Industrial Stainless Steel Heavy Duty Caster Wheels

|

Wheel size

|

Wheel Diameter

|

Tread width

|

Overall Height

|

Top plate size

|

Hole centers

|

Offset

|

Swivel Radius |

Load capacity

|

Qty/ctn

|

|

|

With brake |

Without brake |

|||||||||

|

4*2 inch |

100mm |

50mm |

143mm |

115*100mm |

76/76*92/67mm |

35mm |

134mm |

86mm |

250kg |

16pcs |

|

5*2 inch |

125mm |

50mm |

165mm |

115*100mm |

76/76*92/67mm |

38mm |

144mm |

105mm |

300kg |

14pcs |

|

6*2 inch |

150mm |

50mm |

191mm |

115*100mm |

76/76*92/67mm |

47mm |

144mm |

126mm |

350kg |

12pcs |

|

8*2 inch |

200mm |

50mm |

241mm |

115*100mm |

76/76*92/67mm |

64mm |

168mm |

165mm |

400kg |

6pc |

SUS 304 STAINLESS STEEL MATERIAL

High quality stainless steel SUS 304, contain 8% Ni and 19% Cr.

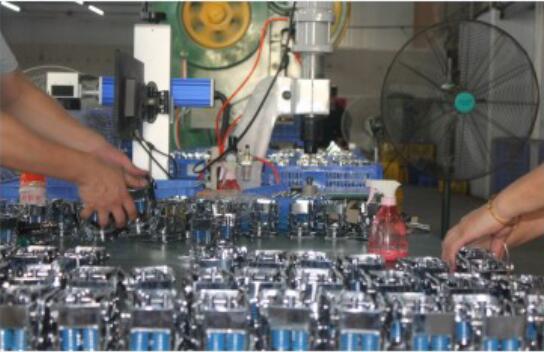

Automatic Stemping Machine

Automatic stemping machine for SUS 304 stainless steel casters, make sure the fast lead time and competitive price.

High-tech production machine

Installation LineTidy and cline production workshop

Test Machine

All our products are made of SUS 304 stainless steel, contain 8% Ni and 19% Cr. Including the top plate bearing balls, bolt and nuts, bush, and all fitings of the fork.

1. Why choose our orange pu casters with nylon brake double ball bearing ?

Good quality and good price, fast lead time and good service.

2. Why our caster with good quality and good price?

We contral the quality very strictly. Our factory is a good managed and tidy factory, with high working efficiency, we have automatic stamping machine to lower the labor cost. Every working step is very smooth and all departments are cooperated very well. So we can lower our price.

For more informations, please click “Send” on below now, you can get free samples!! Looking forward to our corporation.

huanghanbin@zspleyma.com

The following steps are typically included in the caster production process flow: 1. Obtaining raw materials: Select materials suitable for the production of casters, such as rubber, plastic, and metal. 2. Pretreatment: raw material processing, such as plastic powder processing and metal quenching and annealing. 3. Molding: By injection molding, extrusion, and other methods, raw materials are formed into the shape of casters. 4. Assemble the caster by assembling the tires, bearings, steel wires, and other components. 5. Inspection: Quality control of finished casters, including careful examination of appearance, size, bearing capacity, and other indicators. Pack certified casters for storage and transportation. The above is the general process flow of caster production; however, different types and specifications of casters may differ.