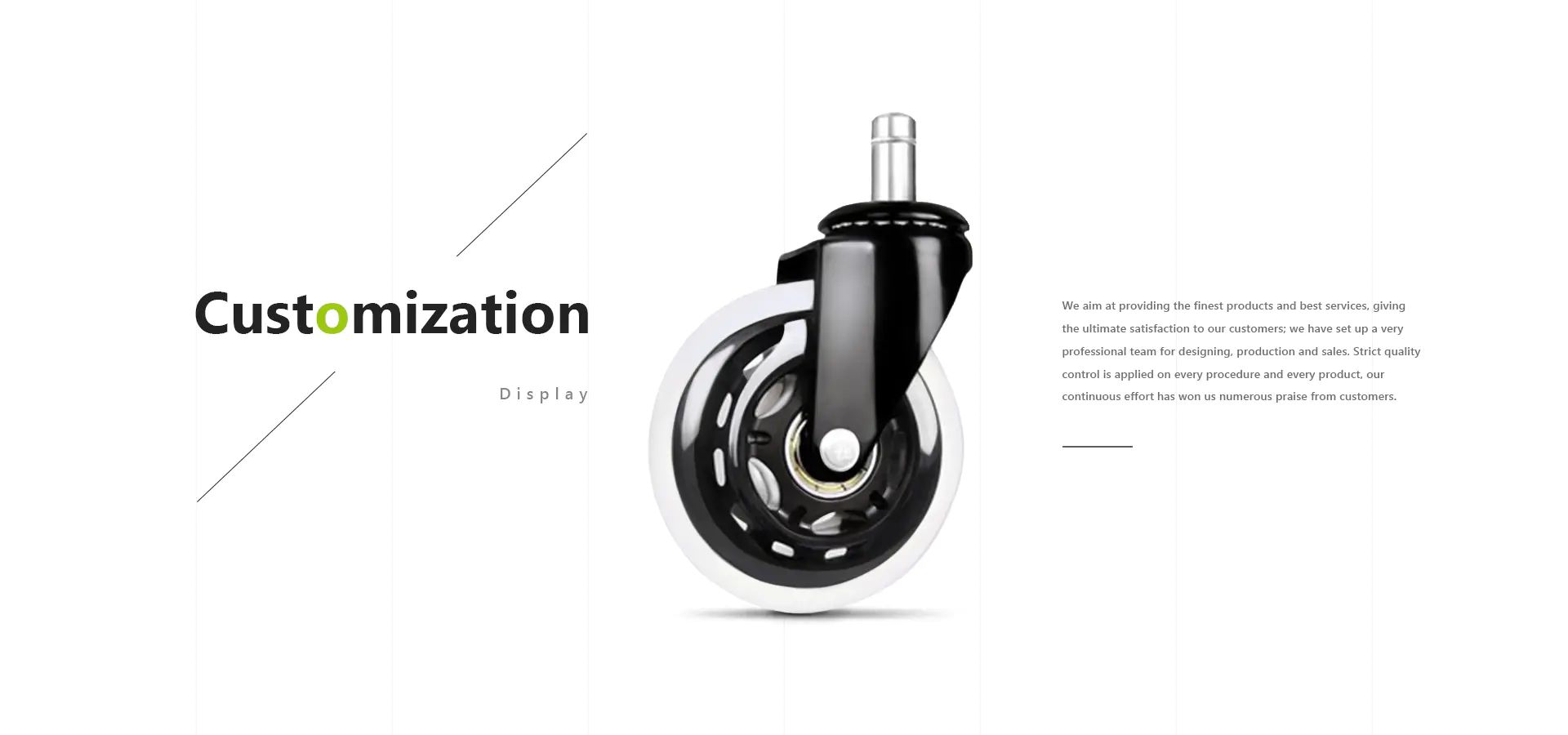

CUSTOMIZATION

PROCESS

Professional caster manufacturers, we are committed to producing high quality products that meet industry standards.

1 - Determine the load capacity of a caster

The net weight of the transport equipment, the maximum load, and the number of single wheels or casters utilized must be specified in order to calculate the load capacity of various casters.

Calculating the load capacity of a single wheel or caster as necessary looks like this: T = M x N (E + Z). T is the required load capacity for a single wheel or caster, E is the net weight of the transportation equipment, Z is the maximum load, M is the quantity of single wheels or casters employed, and N is the safety factor (about 1.3 to 1.5).

2 - Select the wheel or caster's material.

Road width, barriers, lingering materials in the application area (such as oil and iron fragments), surrounding circumstances, and floor surfaces should all be taken into account (such as high temperature or low temperature, humid;carpet floor,concrete floor,wood floor etc.)

Different specialized regions can use rubber casters, PP casters, nylon casters, PU casters, TPR casters, and anti-static casters.

3. Choose the caster diameter.

The weight capacity and ease of movement increase with the caster's diameter, which also serves to protect the floor from harm.

The required load capacity should guide the choice of caster diameter.

4 - Select the caster's mounting options.

According to the design of the transport equipment, mounting types generally include Top plate fitting, Threaded stem fitting, Stem and Socket fitting, Grip ring fitting, Expanding stem fitting, and Stemless fitting.

On the basis of the aforementioned, we can provide you the best caster solution or create new molds for your equipment.

China Food Service Trolley Caster: Enhancing Efficiency and Mobility

Why Choose Pleyma Caster Wheels?